Air storage systems play a crucial role in the manufacture of various mechatronic devices and products today. Valves utilize air storage to control the energy of compressed gases. The device that converts this energy into motion is called a pneumatic actuator. Pneumatic actuators are typically driven by electric compressors and can generate linear or rotary motion.

What is an air distributor?

Compressed air storage systems are known as compressed air systems, but in some cases, they can be considered automated control systems. Compressed gas (usually dry or purified air) is used to start, operate, and stop actuators. Originally, compressed air storage systems resembled the human respiratory system in that they compressed the air forced into the lungs. This compressed air could be used to ignite a fire or shoot arrows. The word “compressed air storage system” comes from the Greek word for “to blow.”

What is an air collection system?

A compressed air storage system is a system that uses compressed air to generate power. It draws in air and passes it through an electrical circuit to provide the required energy. Therefore, compressed air storage systems are widely used in various industries.

Pneumatic battery systems are widely used in industry and everyday life. For example, dental drills use pneumatic batteries for cleaning teeth. Some musical instruments also require pneumatic components for their operation.

Since knowledge of modeling hydraulic and pneumatic systems is an important topic in the field of mechanical system design, Faraders has published a tutorial video on the FluidSIM software for modeling hydraulic and pneumatic circuits; link below.

What are the main components of a compressed air tank system?

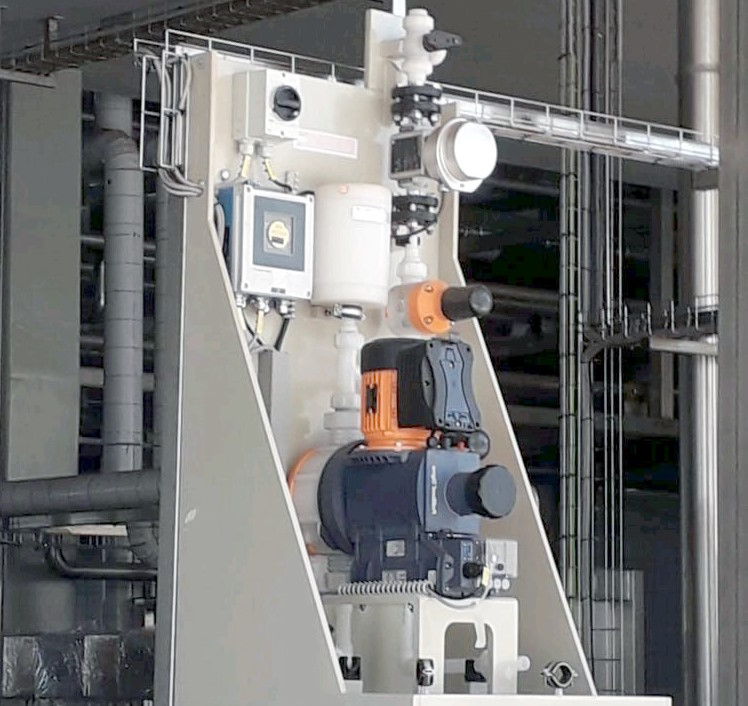

Several components are required to operate an air storage system. First, an air compressor, followed by cylinders. The movement of the cylinders provides the energy needed to operate the motor. The actuator, the third most important component of the air storage system, is responsible for opening and closing the system’s valves. An electric motor, the fourth component of the air storage system, drives the cylinders.

Components of the air collector system

In the previous section, we briefly analyzed the main components of an air energy storage system. In the following section, we will examine each component in more detail.

cylinder

The operating principle of an air storage system is based on the conversion of force into potential energy and the subsequent conversion of this potential energy into kinetic energy using a piston or cylinder. This energy conversion is typically achieved by a piston and a connecting rod. The piston moves linearly, either up and down or sideways.

In a compressed air storage cylinder, compressed air pushes a piston, usually in one direction. Once the piston reaches its end position, the air is released, creating a vacuum. A spring then returns this vacuum to the piston’s starting position.

Lion

Controlling airflow in an air storage system requires several valves, each with a specific function. Soft-start or on/off valves are typically used to start the system. Flow control valves regulate the flow rate. The following are some other valves used in air storage systems.

- Vent valve : Used to release gases from the system.

- Shut-off valve : Used to shut off the outlet valve.

- Safety valve : Used to abruptly stop the system.

- “Air valve” : Regulates the entry and exit of air from the system.

- Solenoid valve : A valve used in more complex systems and operated by electric current; it is also referred to as an “electric valve”.

Call

The various components of the air storage system are connected to each other using connectors. Since all components of the air storage system operate under air pressure, these connections must be fitted with suitable gaskets and rubber seals. These connectors are made of various materials – metals and polymers – and are available in different shapes.

Pipes and hoses

In air-cooled systems, pipes and hoses are used differently. Pipes are typically used in high-pressure systems, while hoses are used in low-pressure systems. The materials used also vary: flexible pipes and polymer pipes are the most common.

Empty section

A vacuum is created when the pressure is significantly lower than atmospheric pressure. To achieve this, all trapped air must be removed, which is done using a vacuum pump or a vacuum generator. These pumps force compressed air through a diffuser, thus creating a vacuum.

Air purification

Compressed air generates heat, which condenses upon cooling, making pumping more difficult. Furthermore, the air contains impurities such as dust and particles. If this contaminated compressed air enters the valves, cylinders, and pipes of the compressed air storage system, it inevitably impairs the system’s function and ultimately leads to its failure.

For the system to function properly, the compressed air must be filtered. This can be easily accomplished with an air filter; however, a pressure regulator is required to control the inlet pressure. Furthermore, the dry air flowing into the system must be lubricated to prevent damage to the equipment.

noise suppression device

The escape of gas from the air storage system is accompanied by a loud noise, which can be reduced by a silencer. This noise can be very loud depending on the strength and pressure of the airflow.

How does the air collector system work?

Pneumatic storage systems operate with their main components, namely compressors, gas cylinders, valves, circuits and actuators.

As explained in this article, all the energy in an air storage system comes from compressed air. Therefore, the system requires at least two main components: one to provide the compressed air itself and another to lift, move, or hold objects.

The first component is the air compressor , the second the drive . A piping system supplies the drive with compressed air; this function is performed by the air storage circuit. For the system to operate correctly, a device for controlling the air inlet and outlet is required; this necessitates valves and shut-off valves .

Another important factor in systems with compressed air storage is the compressed air tank . Due to the high compressibility of air, a system without a compressed air tank would operate very slowly, as the compressor is connected to the drive via a pipeline. Therefore, a compressed air tank is necessary to store compressed air and supply it to the system as needed.

What is the purpose of the air collector?

By combining different components of compressed air storage systems, a wide variety of practical tools can be manufactured. And of course, compressed air storage systems can do everything that electrical and hydraulic systems can. We will discuss which system is better later.

Air batteries are more commonly used in industrial plants than in other devices. In robotics, air battery systems can be used in conjunction with electrical and mechanical systems to power robotic arms. In the dairy industry, air batteries are used to supply milk to cows.

In the past (in the 19th century), banks, hospitals and restaurants used pneumatic stacking systems to transport goods through pneumatic tube systems.

Air brakes are used to stop heavy trucks and trains. As mentioned earlier, some musical instruments, such as the organ, also use air reservoirs.

This video introduces the FluidSIM software, which is used to simulate hydraulic circuits and pneumatic accumulators.

Since the simulation of hydraulic and pneumatic accumulator circuits is used in many industrial and academic fields, FaraDres has developed a two-hour training course, divided into two sessions, aimed at people who want to learn how to use simulation software for hydraulic and pneumatic accumulator systems.

The first lesson of this curriculum introduces the application and presents practical examples, focusing on the forward motion of single- and double-acting cylinders. The second lesson explains the practical applications of pneumatic accumulators, including single-stroke, continuous, and stroke motion.

- To watch tutorial videos on modeling hydraulic circuits and pneumatic accumulators with FluidSIM software, click here .

Which is better, an air accumulator or a hydraulic accumulator?

Pneumatic and hydraulic accumulator systems are used for power transmission , particularly piston force, and can be remotely controlled from the compressor without belts or gears. Despite their lightweight construction, both systems generate considerable power. When comparing these two systems, factors such as output power, precision, ease of use, safety, and operating conditions should be considered.

Production capacity

In applications requiring moderate power, high speed, and relatively low precision, pneumatic storage systems are superior to hydraulic ones. Furthermore, fluctuations in air temperature can affect the performance of pneumatic storage systems.

accuracy

Air storage systems are generally less precise and react more slowly than hydraulic systems ( though not always), mainly due to the compressibility and properties of gases (real or ideal). Furthermore, air storage systems are expensive and inefficient because the compressor requires a significant amount of electrical energy to operate.

control

Compared to high-performance geared motors with high inertia, pneumatic energy storage systems require less energy for starting and stopping. Therefore, pneumatic and hydraulic energy storage systems offer advantages depending on the application.

user-friendliness

Battery-powered pneumatic tools generally require less force and pressure, resulting in smaller dimensions and lighter weight. They can also be made of lightweight plastic, whereas hydraulic tools require metal components to withstand higher forces and pressures.

Protection

All these systems are susceptible to gas and fluid leaks. To ensure a leak-proof hydraulic system, suitable seals and O-rings must be used. Furthermore, since hydraulic oil is flammable, its safety is lower than that of systems with pneumatic accumulators.

Terms of Use

Since hydraulic machines are operated with oil, they do not require separate lubrication and operate more quietly.