What is a dosing pump?

What is a dosing pump or measuring pump ?

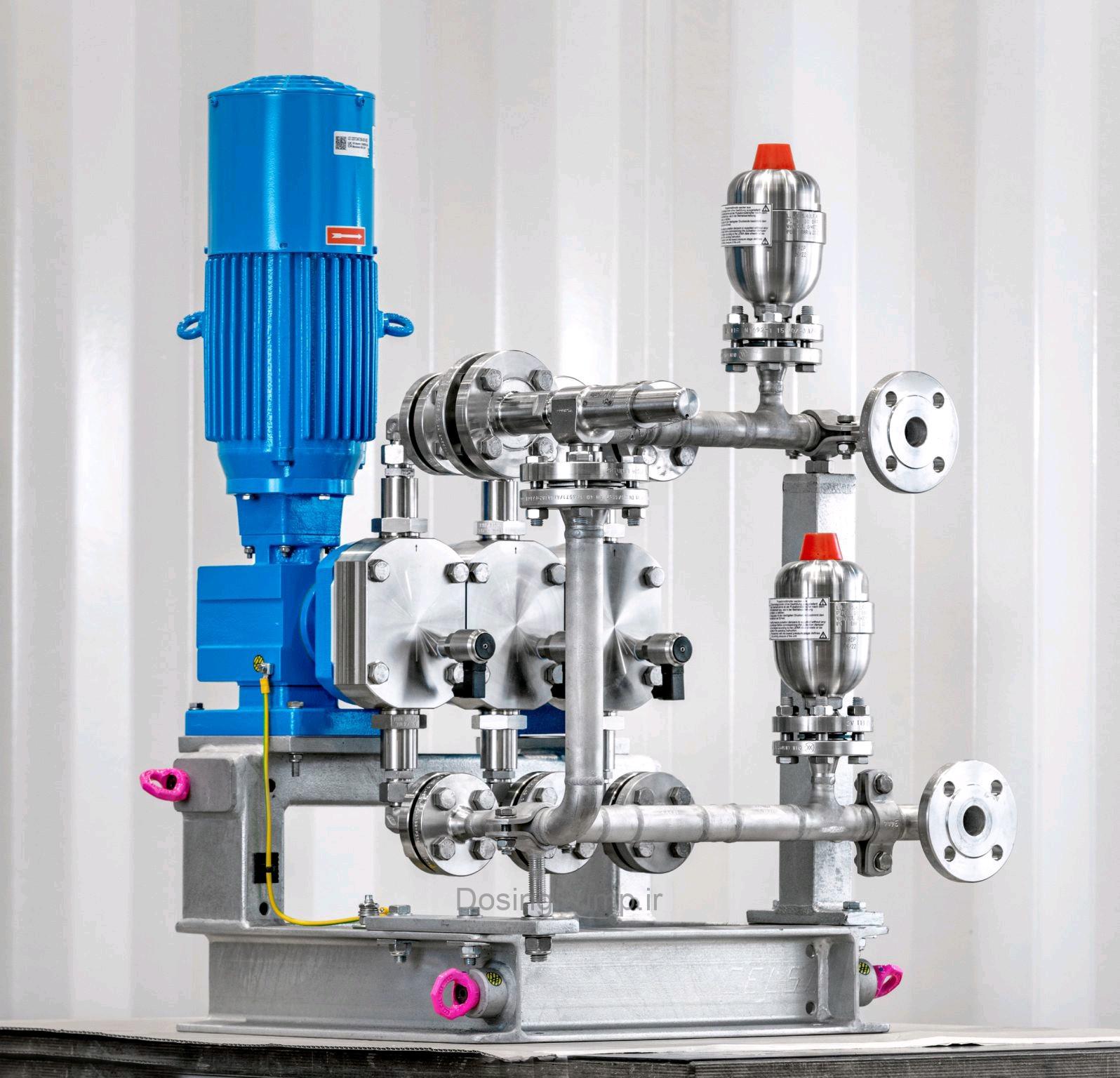

Dosing pumps or in other words metering pumps are pumps that pump or inject a specific amount or dose from a fluid.

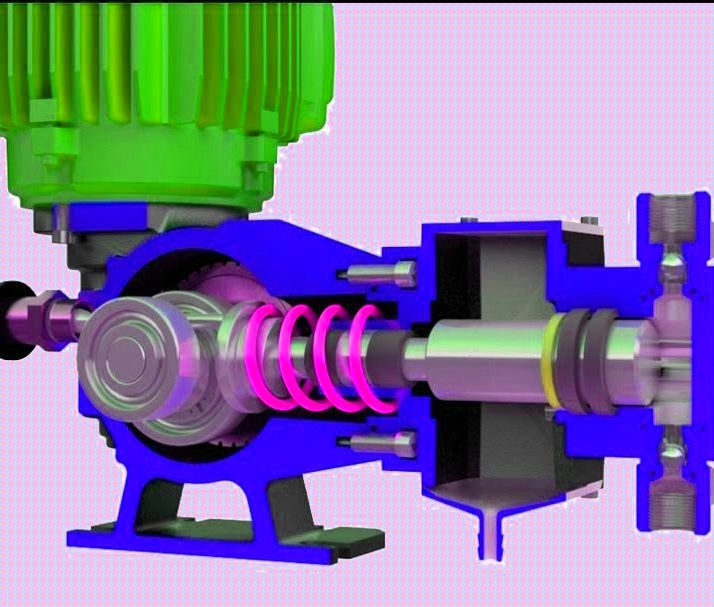

These pumps are available in two types: piston and diaphragm dosing pumps.

Dosing pump application

Dosing is used for chlorination and injection of acid and alkali and in general injecting a certain amount of fluid into tanks and pools or into pressurized pipes.

The dosing pressure of the pump to the atmosphere is determined by a water meter or bar.

The viscosity of the injected substance is effective in choosing the dosing pump .

The flow rate of the dosing pump is adjusted manually or automatically, and according to the use of metering pumps, there is no need for a high flow rate.

Usually, the dosing range is between 1 liter per minute and 10000 liters per minute and the working pressure is between 10 bar and 2000 bar.

Dosings have accuracy that this number is written on the device by the manufacturer

Dosing pumps generally have an accuracy of 1%.

You can see the uses of dosing below

- Acid injection for pH stability

- Injecting alcohol into gasoline

- Injecting bleach into paper pulp

- Adding components to medicine

- Injection of chlorine and chemicals in water treatment systems as chlorine dosing

- Injection of chemicals in water disinfection

- Polyphosphate injection for water hardness

- Injection of acids and alkaline solutions to control PH

- Inject concentrate into drinks

- Injecting essential oil in soft drinks

Application of dosing in sugarcane industry

- Washing and cleaning with acid or acid washing

- Chlorination and pH control for water and wastewater treatment in the factory

- Caustic soda injection for washing and cleaning the machine from syrups

A part of the dosing pump is in contact with the chemical substance, we call it Wet .

This part is often made with anti-corrosion materials.

The common types of pump heads are:

A) Poly Propylene:

This material is very economical and is used for most materials with low corrosiveness.

b) PVC:

Compared to polypropylene, this material works almost the same and due to having chlorine in its structure, it is compatible with chlorine.

Therefore, it is more suitable for fluids that have a high percentage of chlorine.

c) PVDF:

This material is compatible with almost all chemicals.

Also, it can withstand more pressure than the previous two types, one of its distinctive features.

d) Stainless Steel:

This material is resistant to impact and its selection prevents damage to the pump head due to human errors.

It is also compatible with many materials.

e) Hastelloy C:

It is a nickel-based superalloy that is highly compatible with all kinds of acids and corrosive substances. This material is used in a place where high pressure does not allow the use of PVDF and SS is corrosive to the chemical. Hastelloy is composed of nickel, chromium and molybdenum elements and is highly resistant to corrosion. Because of the presence of molybdenum, which has a higher mechanical and thermal resistance than other nickel-based superalloys, it is used in it.

g) Pure Teflon PTFE: The advantages of pure Teflon are:

High abrasion resistance

Very high thermal stability

It has the lowest known amount of surface friction

Excellent non-stick properties

It has the highest resistance to chemicals among all polymers