Raw and pre-treated water is somewhat alkaline (pH above 7). RO membrane fibers are based on cellulose and decompose in alkaline conditions, which leads to a decrease in its efficiency. Although membranes can be regenerated using backwash techniques, long-term exposure to alkaline conditions results in replacement of industrial water treatment membranes , which incurs a significant capital cost.

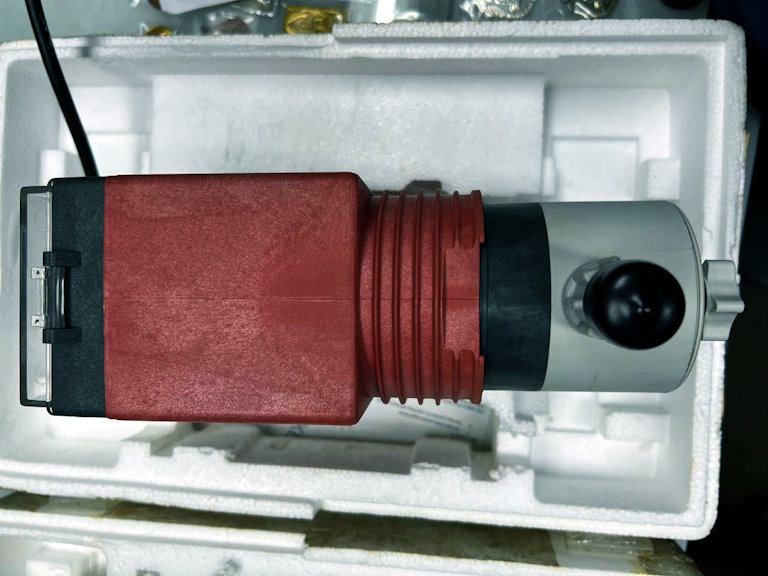

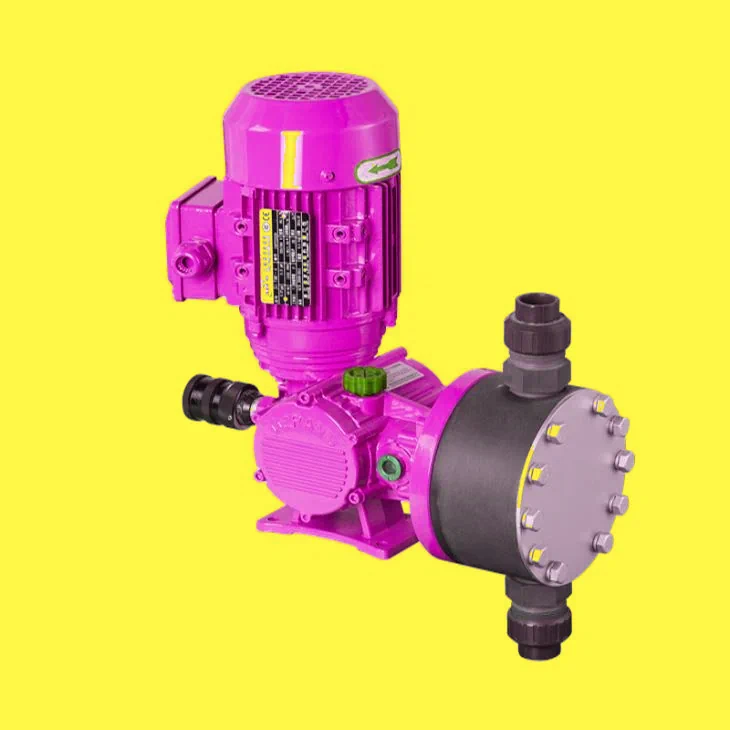

To protect the membranes, the pH of the alkaline raw water should be adjusted to neutral (approximately 7). This is done by injecting precise amounts of acids, such as hydrochloric acid, to lower the pH. Considering that the pH of the source water may be variable (due to storms or other human interference), the dosing capability of the pumps should be used only to inject the required amount of acids to ensure the correct pH of the water passing through the membrane.

The purpose of pH control is mainly to protect the RO infrastructure. However, when the permeate passes through the membrane, the treatment process often produces water that is slightly acidic (pH less than 7). To provide the best possible quality water for drinking, the pH must be adjusted once again using alkalis (caustics) or chemicals such as sodium bicarbonate to bring the alkaline state back to neutral pH. Again, dosing pumps are used to inject the precise amounts of caustics required for the process.